Delve into the cultivation and success of duraweb® family of materials.

Picture PBS International as a flourishing plant, extending its roots across the globe to assist plant breeders. Every story has to begin with a single seed, and for us, that seed is our duraweb® material.

In this article, we aim to provide you with an in-depth understanding of PBS International’s duraweb® materials, trusted by breeders and seed producers for over 50 years now, and how these materials can revolutionise your work too.

Introducing our duraweb® material

Our materials define our uniqueness, serving as the foundation for everything we do, from our pollination control bags to our tents.

So what exactly is duraweb®

duraweb® is made from a non-woven fabric. (Did you know: non-woven fabrics are used in a wide range of well-known products; such as wipes, face masks, clothing, tea bags and more?)

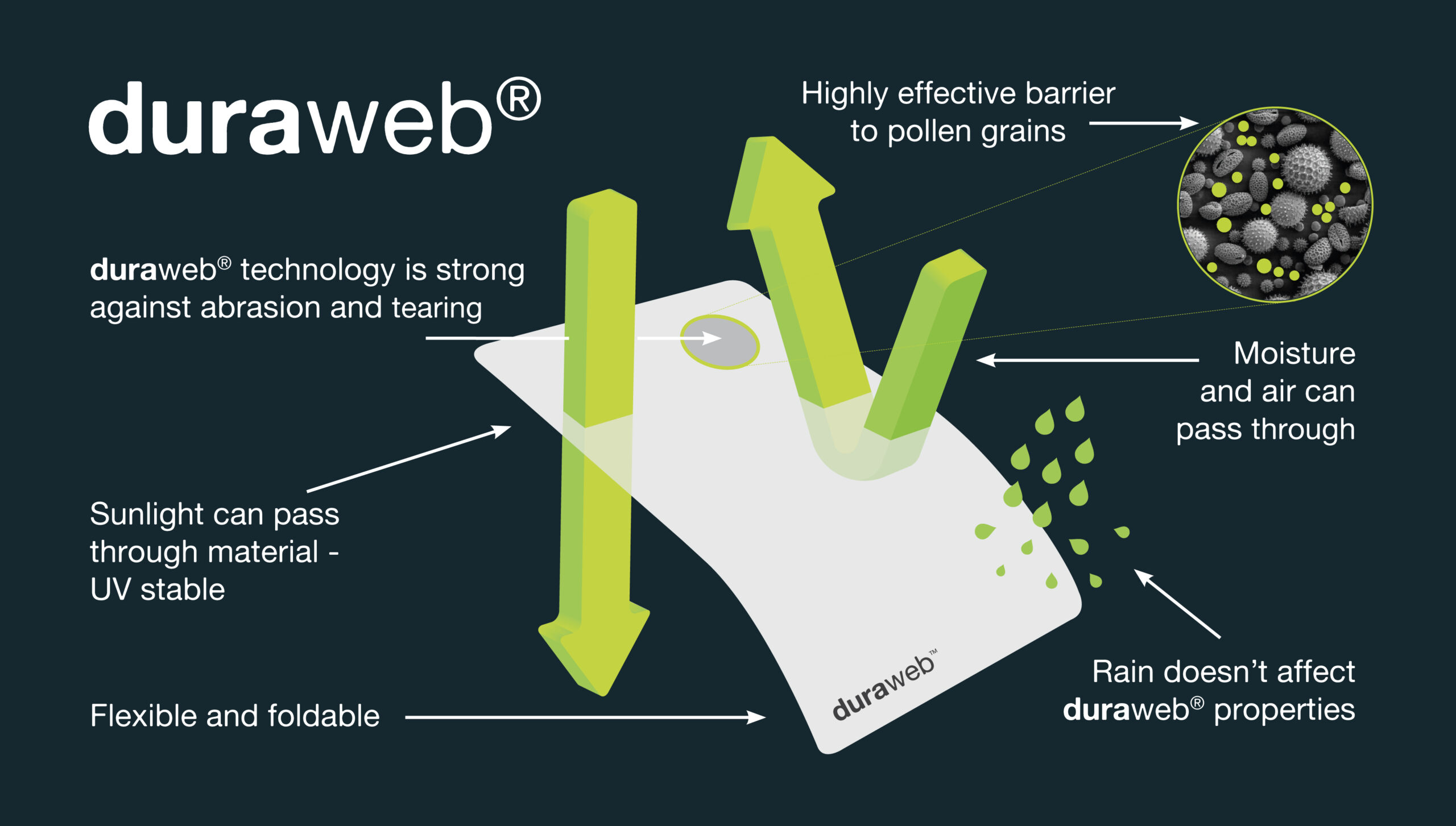

We offer a range of different duraweb® materials collectively known as our ‘duraweb® family of materials.’ Each variation is designed to meet a different challenge faced by plant breeders worldwide. For example, in hot parts of the world, breathability and able to withstand high levels of UV is the priority, whereas in other parts of the world strength and robust products for stormy weather conditions is a more important objective. Our materials excel in addressing these diverse needs, all while keeping unwanted pollen from getting through the bag and optimising plant health.

A closer look at the non-woven materials

Nonwoven materials are versatile and used in lots of different ways, a bit like different types of pasta – spaghetti, penne, tagliatelle – each have their different forms but are all fundamentally pasta. Similarly, non-woven materials are thoughtfully designed to meet the specific requirements of how they will be used – and in our case this means always halting unwanted pollen.

The four key factors in designing non-woven materials

Polymer Selection: Different polymers have distinct properties. For example, some polymers have higher melting points influences suitability for certain manufacturing techniques or enhanced UV stability which affects the climates they’re best for.

Fibre Structure: Nonwoven materials consist of fibres, which can vary in length, diameter, and arrangement. Fibre structure affects properties like strength, breathability, and filtration capabilities. For instance, longer fibres create a more robust material, while nanofibers are efficient at filtering tiny particles.

Bonding Processes: To transform loose fibres into a functional material, bonding processes are applied. This creates different textures and properties. For instance smooth surfaces are suitable for protecting sensitive flowers in forestry. Conversely, rough surfaces may provide additional grip.

Post-Production Treatment: After bonding, nonwoven materials can undergo various treatments, these treatments are tailored to specific needs. For instance, some treatments enhance material durability, or other improve flexibility.

What does this mean for plant breeders?

Our materials define our uniqueness, serving as the foundation for everything we do, from our pollination control bags to our tents.

Years of careful observation, research, and trials have led to our range of non-woven duraweb® materials.

While keeping pollen and pollinators out is crucial, other properties also matter. For example, we consider these factors when selecting our products:

Strength

If fabric tears or punctures during a breeding project, the pollen (or pollinating insects) can get in. Our materials can be sturdy enough to cover even spiky and abrasive plants such as palms.

Flexibility

Sometimes the material needs to be rigid so the bag holds itself open away from the delicate and easily damaged flowers, whereas sometimes you need softer material so you can tie it tightly around the delicate stem of a plant.

Transparency

When covering a whole plant, it’s important that light can pass through, but we also consider UV stability so the sun doesn’t cause the material to weaken too quickly over time.

Longevity

Sustainability and longevity are crucial, not only to make our products economical for breeders, but also so they are super reliable. Our tents, especially, are built to last, one reason they have replaceable panels, allowing you to replace individual panels if they get damaged.

These are just four of the many factors we take into consideration when creating pollination control products.

Why does it matter? Why invest in duraweb® products?

The type of pollination bag used on a plant directly influences seed yield, seed health, and the likelihood of successful crosses.

There’s a lot of research highlighting the importance of the type of pollination bags you cover your plant with. If you want a happy thriving plant, it’s logical to provide an environment as natural as possible.

The traditional choices – often paper, plastic, or mesh – frequently fall short in providing optimal results versus higher-tech alternatives. By choosing duraweb® products, you are opting for optimal results. You’re combating challenges while promoting plant health, ensuring the best outcomes.

We hope you enjoyed our article delving into the fabric technology of which your bags are created from, keep your eye out for part 2 where we delve into the shapes, sizes and tailoring that we cover in our products.

Click here to view our full product range